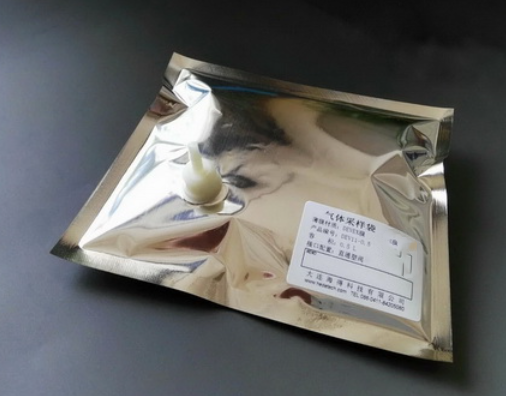

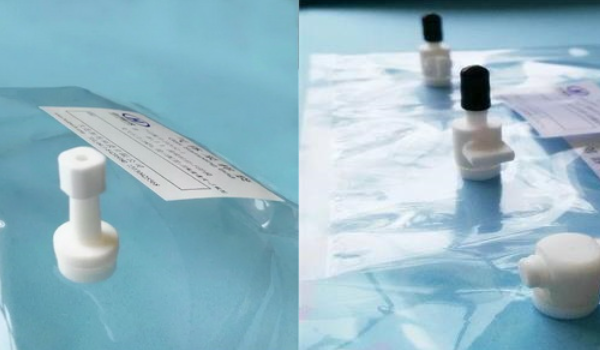

IML-VOC1 Low Pollution Gas Sampling Bag

The thickness of the film is about 75um, which is thinner than the aluminum-plastic composite film, but the elasticity is relatively better. To avoid the aluminum-plastic composite film from becoming cold and hard and brittle, the most important thing is that this film has a very low background and contamination of gas samples. Small, can meet the higher requirements of foreign customers for sampling bags. Compared with aluminum-plastic composite film, VOC film has the advantages of low background, minimal pollution to filled gas samples, good flexibility, cheap price and high cost performance. Especially when the aluminum-plastic composite film gas sampling bag cannot meet the requirements, the cost of using a fluoropolymer sampling bag is too high, and a VOC sampling bag is the best choice.

Features:

The ordinary aluminum-plastic composite film is bonded by a solvent-based adhesive, which can volatilize a large amount of organic volatiles, and there is no doubt about the pollution of gas samples. The inner layer of Devex film is bonded with environmentally friendly adhesives. The amount of organic volatiles (VOCs) in the inner film is extremely low, which can prevent the gas samples in the bag from being contaminated and prevent interference with analysis data. The organic solvent residue of Devex film is 0.1mg ~ 0.3mg / ㎡, which is 5% of the organic solvent residue of aluminum-plastic composite film.

Scope of application:

1. Can be filled with stable chemical properties and weakly chemically active gases such as petroleum cracked gas, natural gas, coal bed gas, soot gas, ambient atmosphere, process reaction gas, widely used in the collection and storage of gas samples such as petrochemical, environmental monitoring, etc. The airbag can ensure that the low-concentration (ppm level) components are constant within 1 to 3 months.

2. Can be used for the collection and detection of non-methane total hydrocarbons.

3. It can be filled with industrial gas such as low content of hydrogen (H2), oxygen (O2), nitrogen (N2), argon (Ar), methane (CH4), carbon monoxide (CO), carbon dioxide (CO2).

4. It is not recommended for high chemical activity, corrosive and oxidizing gases such as nitrogen oxides, strong alkaline gases and halogen gases; some low content such as ppb grade components are also not recommended.

5. Suitable for light-proof sampling of photosensitive gas.

Noted:

• For sulfide and halogen gas, high content such as percentage level or low content such as ppm level is not recommended.

• Because the two-component adhesive used in the aluminum-plastic composite film can volatilize organic substances such as benzene, ketones, ethers, esters, etc., it should be noted that the organic compounds remaining in the aluminum-plastic composite film can precipitate and can pollute the gas in the sampling bag Samples can cause interference with analytical data.

• If the gas sampling bag is reused, it should be replaced and cleaned multiple times.

• The storage time of the gas sample in the sampling bag should not be too long. The specific storage time has a lot to do with the detection time required for experimental analysis, the type of gas composition, temperature and humidity, and pressure. Generally speaking, inert pure gas can be used as Temporary storage containers are recommended to be stored for no more than 72 hours; for common standard gases, flue gases, ambient atmosphere, etc., it is recommended to be stored for no more than 24 hours.

• To reuse the sampling bag, it must be washed and replaced many times. It is recommended to collect the same sample in the same sampling bag, and do not mix them.

• The sample bag is heated and replaced with high-purity nitrogen to reduce the interference of organic precipitates.

• The inflation pressure does not exceed 6KPa. Visual observation is that the airbag is fully bulged, but it is not taut when pressed with fingers. Overpressure filling can cause burst damage to the gas sampling bag.

• During storage and use, keep away from fire and high temperature, and avoid puncture by sharp objects.

• When sampling and cleaning, please do not exceed 80% of the calibration volume. Taking a 1L sampling bag as an example, it is recommended that the sampling volume does not exceed 0.8L.

• For precise experimental analysis, a blank sample bag must be used for comparison and background deduction.

• For high-pressure and high-temperature gas should be sampled under normal temperature and pressure, the specific treatment method depends on the actual situation.

• For negative pressure gas, a vacuum pump with appropriate power and flow rate should be used for sampling.

• For the gas containing particles, dust and aerosol, a filtering device should be used to prevent contamination of the sampling bag, which will make cleaning difficult.