The pump impulse sensor belongs to the pulse quantity sensor, which directly measures parameters and is used to measure the number of piston movements per minute of the drilling fluid pump, calculate the delay time and other derived parameters. It can also be used to determine pump faults or downhole abnormalities. Installed at the pull rod of the drilling fluid pump head, it can also be installed at the pulley or other places that can be matched to measure the pump stroke. The change in sensing distance directly affects the accuracy of pump stroke measurement, and this change often occurs due to human or mechanical reasons, requiring operators to adjust it in a timely manner. However, due to security requirements, this routine operation is restricted, making it impossible to ensure the normal operation of the sensor.

The research team started with how to achieve micro adjustment of the sensing distance between the pump flushing sensor detection head and the sensing head, taking on-site operation safety as the fundamental point. From mechanical principle analysis to preliminary design, after more than 20 method demonstrations, the technical solution of “remote control, micro electric direct push, and adjustable step” was finally established. In the sample production, full consideration was given to meeting the all-weather application environment, and each component was miniaturized and integrated into a compartment arrangement.

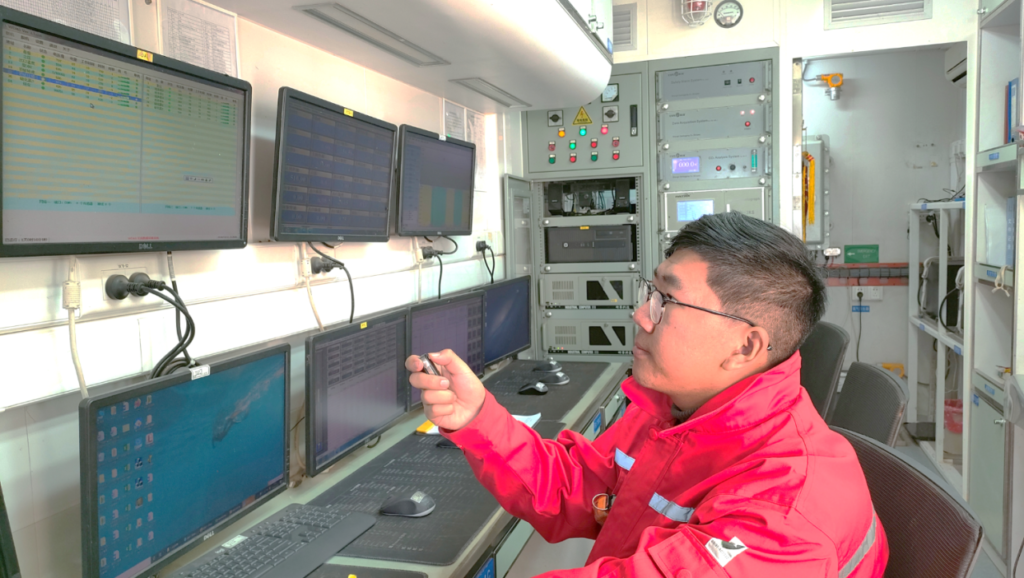

At present, the device has passed comprehensive and multi angle remote control tests within a range of 100 meters at the logistics base, and remote control tests have been conducted both inside and outside the instrument room in the well site environment on the Tuo 123 Xiexie 64 well constructed by the SL205 team, proving its good remote control effect.